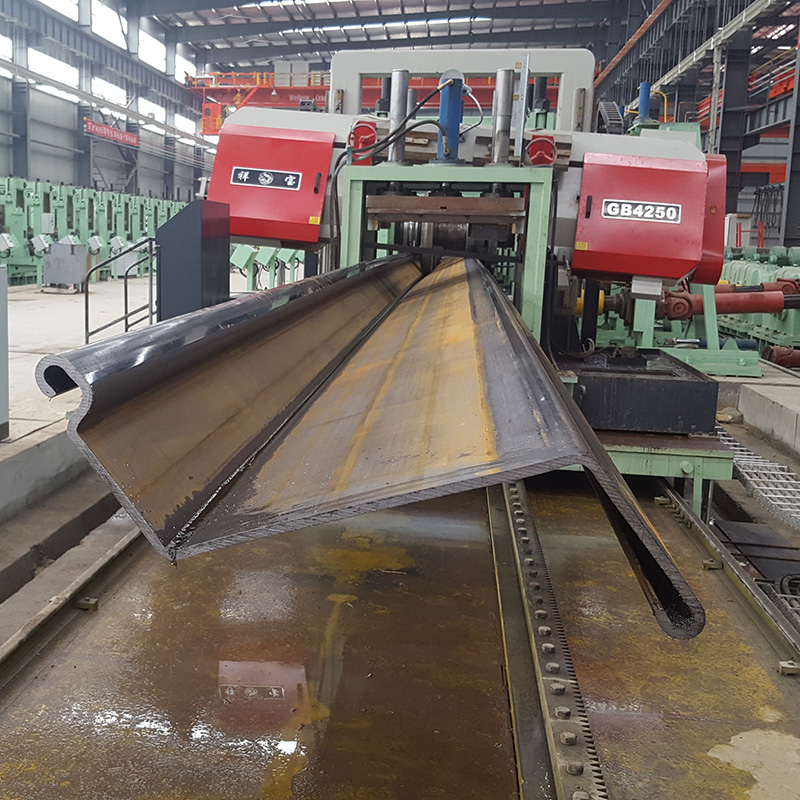

Intsimbi yentsimbi ixhomekeke kwi-deformation eqhubekayo yokugoba ukwenza i-Z-shaped, i-U-shaped okanye enye imilo kwicandelo, enokuthi idibaniswe omnye komnye ngokutshixa ukwakha iipleyiti zesiseko.

Iimfumba zentsimbi yentsimbi eziveliswa ngokuqengqeleka kokwakheka okubandayo zezona mveliso ziphambili zentsimbi eyenziwe ngokubanda kubunjineli boluntu. Iimfumba zentsimbi ziqhutywa (zicinezelwe) kwisiseko kunye nomqhubi weemfumba ukuze zidibanise ukwenza udonga lwentsimbi yentsimbi yokugcina umhlaba kunye nokugcinwa kwamanzi. Iindidi ezisetyenziswa ngokuqhelekileyo ezinqamlezileyo zezi: U-U-shaped, u-Z-shaped kunye nohlobo lwewebhu oluthe ngqo. Iimfumba zamaphepha entsimbi zifanelekile ukuxhasa iziseko ezithambileyo kunye nemingxuma yesiseko enzulu enamanqanaba aphezulu aphantsi komhlaba. Ulwakhiwo lulula, kwaye iingenelo zalo lusebenza kakuhle lokumisa amanzi kwaye lunokuphinda lusetyenziswe. Ubume bokuhanjiswa kweemfumba zeshiti zensimbi Ubude bokuhanjiswa kweengqungquthela zentsimbi ezibandayo zi-6m, 9m, 12m, 15m, kwaye zinokucutshungulwa ngokweemfuno zabasebenzisi, kunye nobude obude be-24m. (Ukuba umsebenzisi unemfuno yobude obukhethekileyo, unokucetywa xa uyala) Imfumba yeshiti yensimbi epholileyo ihanjiswa ngobunzima bokwenene, okanye ubunzima bethiyori. Ukusetyenziswa kweemfumba zentsimbi epholileyo eyenziwe ngentsimbi eneempawu zolwakhiwo olufanelekileyo, inkqubela phambili ekhawulezayo, akukho mfuneko yezixhobo ezinkulu zokwakha, kunye noyilo oluncomekayo lwenyikima kwizicelo zobunjineli boluntu, kunye nemilo enqamlezileyo yeemfumba zentsimbi ezibandayo ezinokutshintshwa ngokweemeko ezithile zeprojekthi kunye nobude, ukwenza uyilo lolwakhiwo lubenoqoqosho ngakumbi kwaye lube sengqiqweni. Ukongeza, ngoyilo oluphuculweyo lwecandelo lemveliso yemfumba yentsimbi eyenziwe ngokubanda, umgangatho womgangatho wemveliso uphuculwe kakhulu, ubunzima ngemitha nganye yobubanzi bodonga buncitshisiwe, kwaye iindleko zeprojekthi zincitshisiwe.

Isixhobo sinezibonelelo ezilandelayo:

● Ukuphucula ukusebenza komsebenzi kunye nokusebenza kwemveliso

● Iqondo eliphezulu lokuzenzekelayo, ukunciphisa igalelo labasebenzi

● Ukuphucula imeko yokusebenza kunye nokhuseleko

● Ukuphucula ukuzinza komgangatho wemveliso, ukubumba okuzinzileyo nokuthembekileyo, kwaye kunokuhlangabezana nokuveliswa kwezinto ezinobunzima obuhlukeneyo kunye namandla.

●Phucula imveliso yemveliso

● Ukunciphisa iindleko zezixhobo

● Ukusebenzisa i-software yoyilo loyilo loyilo lwe-COPRA yokwenene yaseJamani, ngokuhlalutya ubunzima benkqubo yokubumba iprofayili egobayo, eyona nkqubo ifanelekileyo yokugoba epholileyo kunye nokudlula kwe-deformation inokumiselwa ngaphambi kokuba umqulu uqulunqwe, kwaye iteknoloji yokulinganisa i-finite element ingasetyenziselwa ukulinganisa. Kwinkqubo yokuqulunqa umqulu obandayo, uyilo lomqulu luphuculwe, kwaye kukho i-stress-straining esetyenziselwa ukulinganisa indawo eyingozi. uyilo.

● Ukuze ugcine ixesha lokutshintsha ii-rolls xa utshintsha i-specifications, i-shafting ekhawulezayo yokutshintsha kunye ne-drive shaft-dissingagement devices, kunye ne-roll-changing tooling zilungiswa.

Ixesha lokuposa: Feb-21-2023